Products

Rejector Systems

INQUIRYRejector Systems

With over 50 years’ experience in the design and manufacture of inspection and detection equipment, ANRITSU provide the best solutions that suit customers' needs.

It is common to place a rejector system after an inspection system at the food facility for the below reasons.

1. Prevent the production downtime from stopping the line when the error occurs.

2. Prevent a careless mistake (put back defective products to the line) by an operator.

2. Prevent a careless mistake (put back defective products to the line) by an operator.

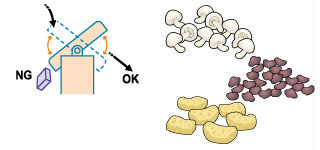

Flipper Type

The most common type of rejector is the flipper. NG products are pushed aside by the rejector gates (arms). It is ideal for products in boxes and thick bags.

Introduction video:

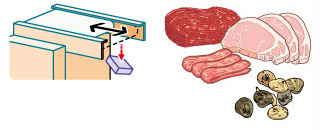

Dropout Type

The rejection conveyor drops down to reject NG products. It is ideal for products in thin bags.

Introduction video:

Up and Out Type

The rejection conveyor flips up so that the NG product drops out of the line. It is suitable for products in thin bags.

Introduction video:  Up and Out Type

Up and Out Type

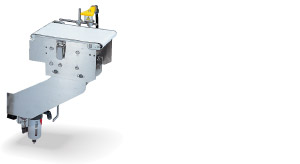

Air Jet Type

NG products are blown sideways off of the line by a powerful blast of air. It is ideal for small, lightweight packaged products at high speed.

Introduction video:  Air Jet Type

Air Jet Type

Trip Type

In this unusual belt method, NG products are carried off either left or right by belts running crosswise to the product flow. It is suitable for rejecting large packaged products.

Pusher Type

NG products are pushed off the line sideways by the action of a gate attached to an air cylinder. It is suitable for rejecting products in packages and thick bags.

Introduction video:  Pusher Type

Pusher Type

Turning Type

This method uses a turning gate to reject NG products. It is suitable for rejecting products in large packages and in thick bags at comparatively highspeed.

Carrier Type

NG products are sorted horizontally without any shock due to rejection. Since the rejection process doesn't cause any damage, it is ideal for fragile products.

Chute Type

Rejected products fall when the chute is reversed. It is ideal for rejecting relatively light bulk products.

Introduction video:  Chute Type

Chute Type

Shuttle Type

The conveyor on the rejector slides to let the rejected products fall during the rejection. It is ideal for unpackaged animal products and sticky bulk products.

Introduction video:  Shuttle Type

Shuttle Type