Products

Anritsu X-ray Inspection System XR75 series Large model

INQUIRY

Anritsu X-ray Inspection System XR75 series Large model

X-ray machines are quality system equipment for the detection of all types of impurities in both food and non-food products. X-ray machines are used in industries such as food production, fisheries, meat and vegetable processing, pharmaceuticals, cosmetics, textiles, recycling and other industries. X-ray machines are designed for the inspection of both prepacked and bulk products and can be used not only for solid but also for liquid products, as well as for frozen or hot products.

Anritsu XR75 Series Large model suitable for large boxes, bags and containers.

Advanced X-ray technology and simple operation help improve product quality.

In addition to detecting metal contamination, X-ray systems can also identify shape defects, missing and broken objects. The Anritsu XR75 X-ray inspection system for large products is suitable for inspecting products in large cartons, containers and bags. The system delivers consistent and reliable inspection results across your production line with excellent detection sensitivity, ease of operation and improved durability.

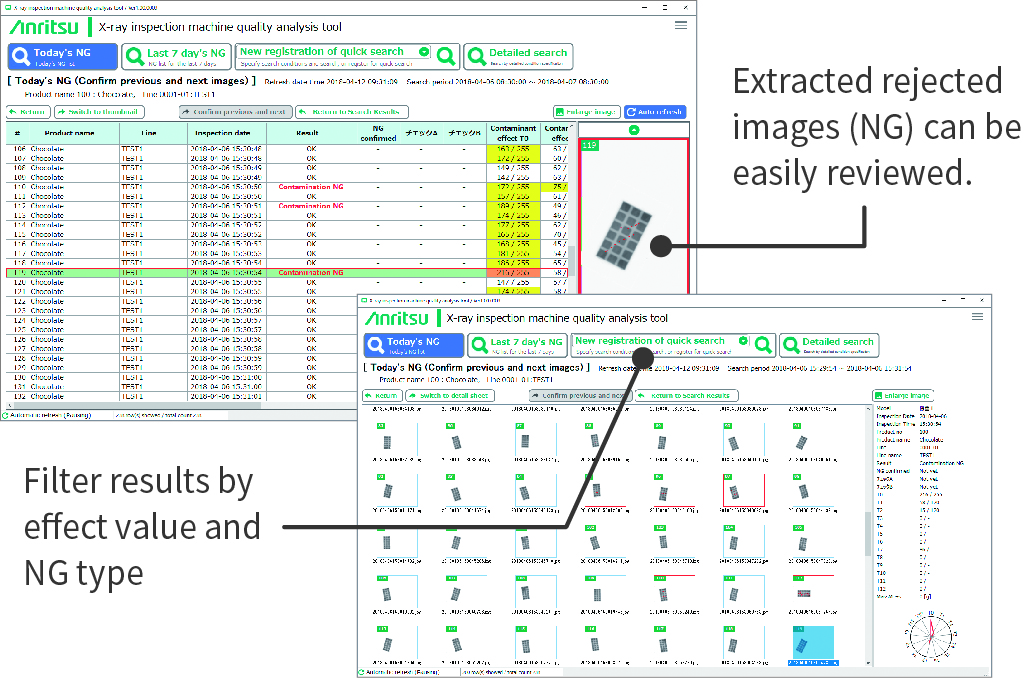

Intuitive, time-saving software

The XR75 software helps operators work more efficiently by displaying rejected images on screen for easy contaminant identification.

.jpg)

Example: flour packed in a large bag.

Improvements from previous models

- Conveying capacity

The XR75 for large products is equipped with a heavy-duty motor that allows the system to transport dry products up to 50 kg and wet products up to 40 kg.

- High rigidity of moving parts

The rigidity of moving parts such as the conveyor cover and motor is improved by continuous testing using intensity analysis.

- Several options are available

Extendable conveyor and extension cover can be selected as an option according to the length of the product.

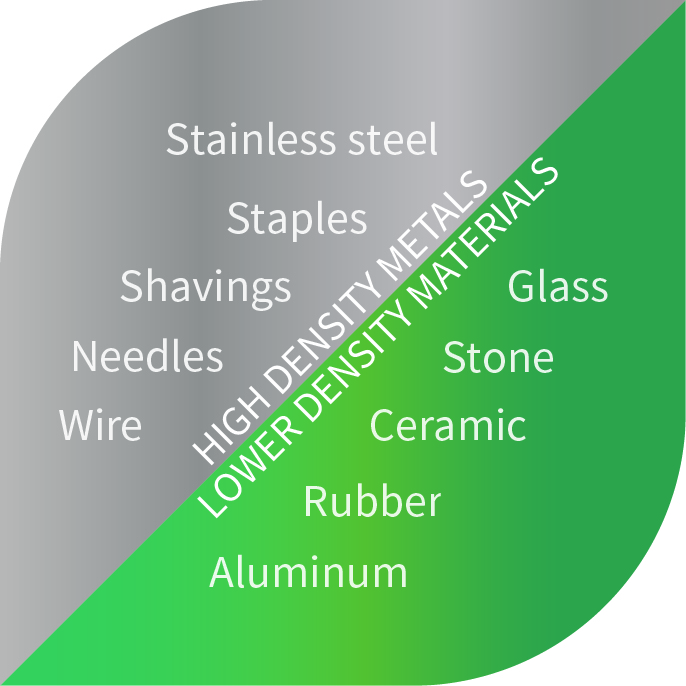

Not only metal

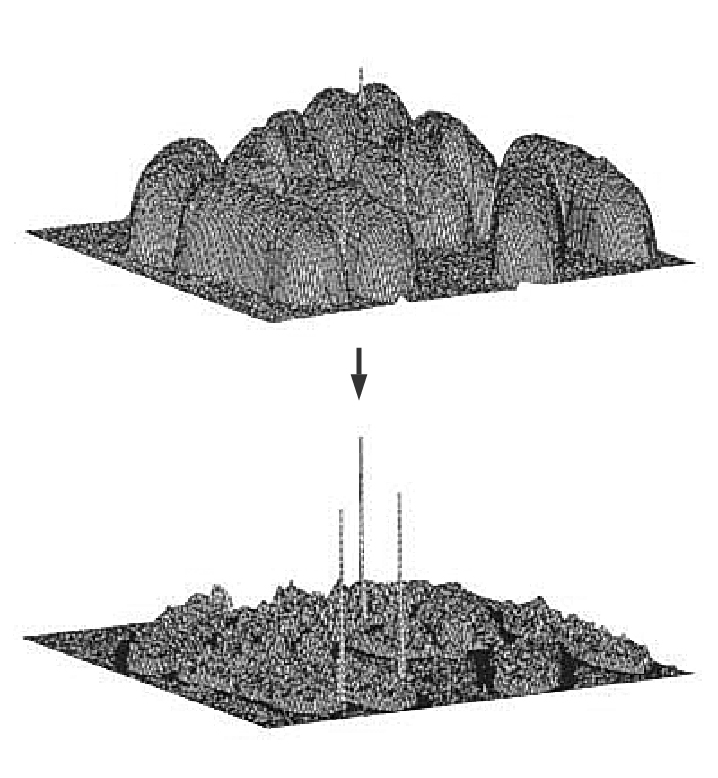

Latest algorithms

Anritsu signal processing technology and image processing algorithms accurately capture the contamination signal. An advanced algorithm offers improved detection sensitivity, allowing the system to easily detect low-contrast contaminants such as bone and plastic.

Thorough quality control and analysis

All information is easily accessible from anywhere using QUICCA 3 - Total Quality Management and Quality Control. Each X-ray image is automatically saved during inspection for complete product traceability. The quality analysis function allows the processor to view both before and after images of rejected product on screen, helping to find potential future problems before they occur.

Anritsu X-Ray Machine XR75 series Large model in action