![]()

Side View X-ray Inspection System

HIGH-LEVEL DETCTION with ANRITSU X-RAY INSPECTION SYSTEM

Anritsu Side View X-ray Inspection System applies renown XR75 technology.

Anritsu HD imaging technology XR75 is widely used for product inspection from above (world leader in the number of installed equipment) and now this high technology is used for inspection of products from the side - inspecting products in flat-bottom packaging such as cartons, foil-covered packages, beverage packages and PET bottles. HD imaging is a standard feature in all XR75 machines, providing excellent detection of both high- and low-density contaminants smaller than 0.5 mm*.

* The actual sensitivity depends on the physical properties (contents and shape) of the products and conditions.

|

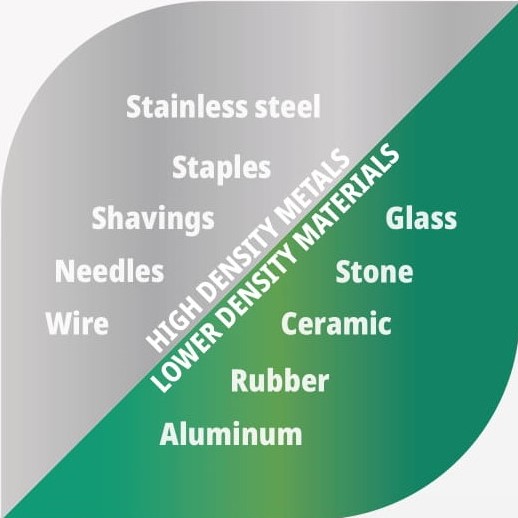

Broader detection range ANRITSU X-ray Inspection Systems ensure accurate and repeatable detection of contaminants. |

Intuitive and time-saving software |

|

XR75 X-ray Inspection System software allows operators to work more efficiently on identifying NG (contaminated) products on the screen. |

|

|

DETECTION EXAMPLES

| Juice in PET bottle | Potato chips in cylinder box | Ketchup in PET bottle |

|

|

|

More than 12 000 of installed units

| ANRITSU #1 |

Worldwide supplier of food and pharmaceutical X-ray inspection equipment

|

Among equipment manufacturers, Anritsu is the leader in the number of units installed worldwide. Anritsu customers value Anritsu's 50 years of performance and reliability in the industry, based on precision engineering and product safety as a priority. |

Easy to use and maintain

In addition to incomparable detection performance, the XR75 Side View X-ray Inspection System ensures low maintenance costs and proven reliability.

XR75

Features that your production team will appreciate

• Side View in a touchless system (with no curtains) reduces product jamming and handling problems.

• Intuitive interface is used in both Anritsu X-ray Inspection Systems, checkweighers and metal detectors, resulting in reduced downtime and training time and fewer errors. Configure products in a few minutes using Setup Wizard and Auto-learning option.

• Anritsu QuiCCA QA software offers real-time monitoring, traceability, reporting and compliance with HACCP (optional function).

|

|

| Available reject kits: Air blast or high-speed ejector. | Removable end plates are available to match multiple product sizes (optional). |

SAFE DESIGN

Anritsu believes that customer safety is of key importance.

|

X-ray ON/OFF key |

|

|

|

Emergency stop switch |

X-ray access door locking |

|

|

Hand insertion sensor |

|

|

SAFETY MANAGEMENT

Although Anritsu X-ray Inspection Systems are designed to ensure safe operation, we recommend to follow ANRITSU rules provided below to achieve the highest level of safety.

1. Periodic measurement and registration of X-ray leakage data.

2. Management of the operator's working hours.

3. Additional safety measures

Depending on the shape and packaging of the products, it may be necessary to install covers on the upstream and downstream conveyors.

4. Disassembly or modification of the equipment is prohibited

NEVER modify or disassemble the main unit, covers, safety covers, safety locks, etc.

Safety of inspected products

In 1980, the WHO concluded that irradiation of any food with an overall average dose of 10 kGy poses no toxicological risk and does not cause specific nutritional or microbiological problems.

The maximum dose of X-ray irradiation to products to be inspected by Anritsu X-ray Inspection Systems is 0.002 Gy, which is much lower than the value described above. Even if the product remains inside the X-ray Inspection System when it stops operating, the X-ray dose is always kept at 0.1 Gy or less.