Products

GoDEX label applicator

INQUIRY![]()

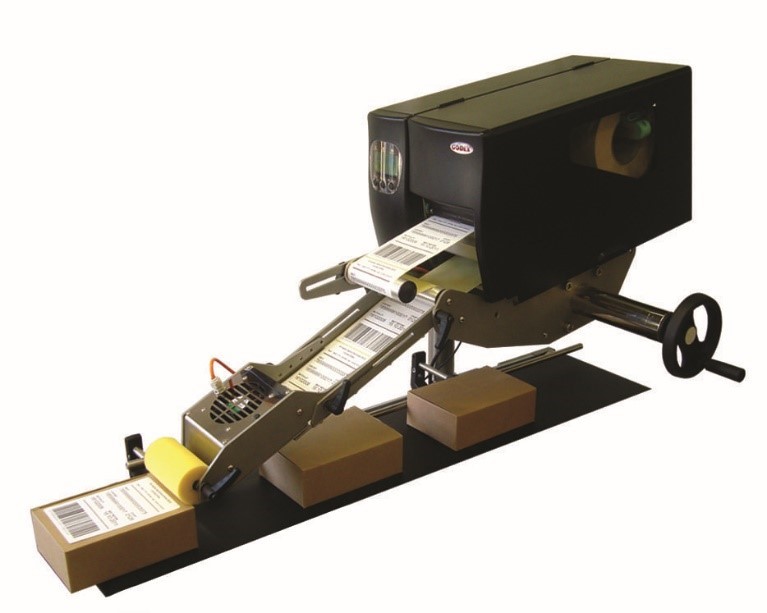

GoDEX AG2000 label applicator

Godex AG2000 is definitely the most cost-effective printing and labelling solution for optimization of label printing and application on finished products at the end of the line, as it offers great flexibility, exceptional durability and ease of use at a low cost. This system is designed to print and apply labels onto moving products and articles during their transportation on a conveyor. The equipment consists of an applicator head and a GoDEX industrial label printer, which also allows the labelling of articles of irregular shape.

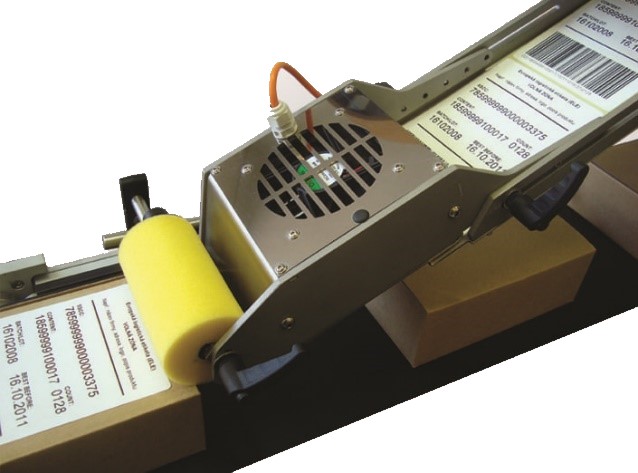

The GoDEX AG2000 label applicator is designed to automatically apply self-adhesive labels on articles with a flat surface and of identical shape. It is able to apply labels on either the top or the right side of the article. Combined with GoDEX EZ-2000 and GoDEX ZX 1000i printer series, the AG2000 system is a very cost-effective labelling solution for anyone looking for optimization of the line labelling process, as it offers great flexibility, exceptional durability and ease of use at a low cost. The applicator consists of a control unit and three main mechanical parts: a bracket that supports the printer, a height adjustable applicator arm to easily adjust to various box- and product sizes, and a ventilator unit.

Max. system speed – 175 mm/second (depending on the maximum print speed).

Max. length of a label – 150 mm, width – 110 mm.

GoDEX AG3000T

Pneumatic tamp applicator for printing and applying labels

The GoDEX AG3000T system combined with GoDEX printer series ZX1000i with high-end pneumatic tamp applicator for printing and applying labels. They come with standard applicator heads of 60 mm x 60 mm or 100 mm x 100 mm. Although this system is usually used to label non-moving articles, it can also be used to label moving articles. There are various options to customize the AG3000T / AG3000-LS to your specific needs.

VIDEO